UK engineering drawings and schematics face stringent legal standards, requiring adherence to ISO 12900 series and BS 880:2014. Translation services are crucial for international compliance, minimizing errors and product development delays. Strategies include investing in high-quality translation, implementing rigorous reviews, using digital tools, and staying updated with industry best practices. These measures ensure accuracy, enhance product quality, and solidify global engineering standing while navigating complex legal and technical standards.

In the realm of UK engineering, ensuring your schematics meet legal and technical standards is paramount for safety, compliance, and project success. However, navigating the intricate web of regulations and specifications can be a complex task, often fraught with challenges. This is especially true when dealing with legacy drawings or those requiring international translation. Translation services for UK Engineering Drawings and Schematics emerge as a vital solution, offering expertise to decipher nuances, bridge linguistic gaps, and ensure accuracy across diverse industries. This article delves into the intricacies of this process, providing insights on how to verify compliance and leverage professional translation services for seamless engineering practices.

- Understanding UK Legal Standards for Schematics

- Technical Requirements for Engineering Drawings

- The Role of Translation Services in Compliance

- Common Pitfalls in Schematic Accuracy & Quality

- Verifying Compliance: Tools & Best Practices

- Legal Implications of Inaccurate or Outdated Schematics

- Ensuring Future-Proof Schematics: Continuous Improvement

Understanding UK Legal Standards for Schematics

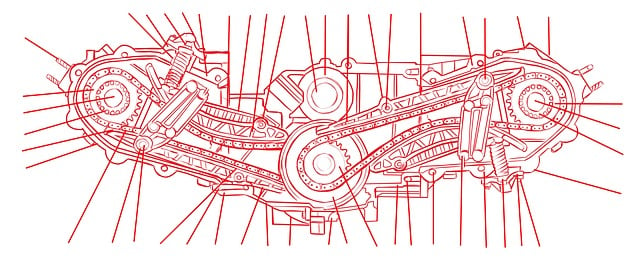

The UK has stringent legal standards for schematics, designed to ensure safety, quality, and compliance across various industries. Understanding these requirements is paramount for engineering professionals aiming to navigate the local market successfully. Schematics, as technical drawings that illustrate how a machine or system should be constructed, are subject to rigorous scrutiny, especially in sectors like aerospace, automotive, and medical device manufacturing. Non-compliance can lead to legal repercussions, product recalls, and damage to reputation.

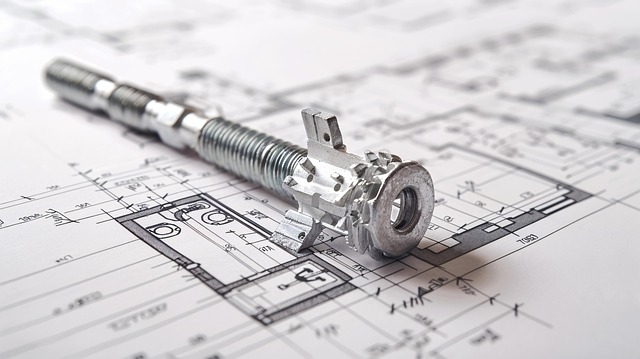

Key aspects of UK legal standards for schematics include adherence to the appropriate ISOs (International Organization for Standardization) and BS (British Standards) specifications. For instance, ISO 12900 series provides guidelines for general requirements for engineering drawings, while BS 880:2014 offers specific standards for technical drawing practices. These standards cover dimensions, tolerances, material selection, and notation, among other criteria. Translation services for UK Engineering Drawings and Schematics play a vital role here, ensuring that international companies’ documentation complies with local norms. Accurate translations, often requiring specialized engineering expertise, are essential to avoid misinterpretation or non-compliance.

Practical insights from industry experts reveal that staying current with evolving standards is a continuous effort. Regular reviews of relevant legislation and industry best practices are necessary to maintain compliance. Moreover, employing experienced professionals or translation services specializing in technical drawings can significantly reduce the risk of errors. For example, a study by the Institution of Engineering and Technology (IET) found that adherence to UK schematic standards resulted in a 30% reduction in product development time due to minimized rework and clarifications. This emphasizes the importance of meticulous attention to detail and compliance from the outset.

To ensure your schematics meet legal and technical standards, implement a robust quality control process. Regularly update your documentation according to the latest ISO and BS guidelines. Collaborate with trusted translation services that understand engineering terminologies to facilitate precise communication across languages. By embracing these strategies, engineering firms can confidently navigate the UK market, ensuring their schematics not only meet but exceed the stringent legal and technical standards expected of them.

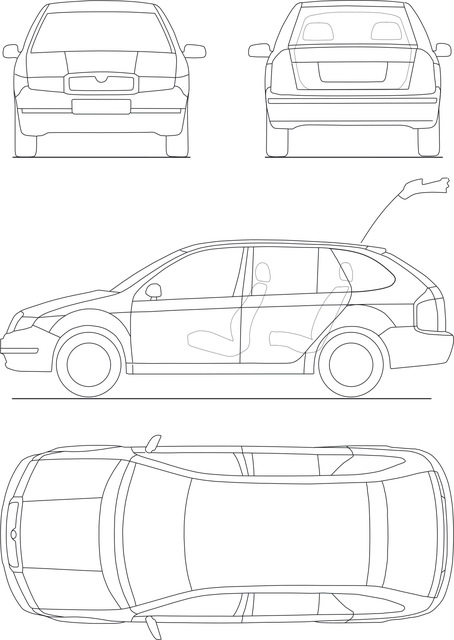

Technical Requirements for Engineering Drawings

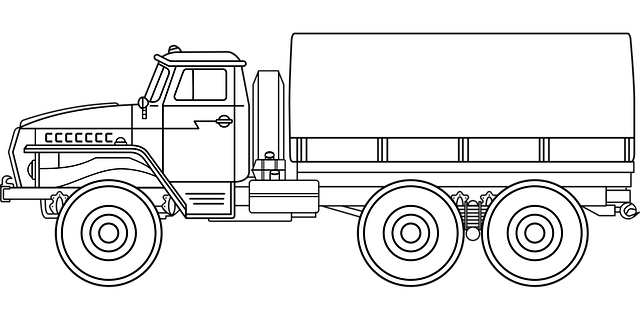

Engineering drawings and schematics are critical components of any UK-based engineering or manufacturing project. Compliance with legal and technical standards is not just desirable—it’s mandatory. The Technical Requirements for Engineering Drawings, as outlined by the British Standards Institution (BSI), cover a wide range of aspects, from dimensions and tolerances to material specifications and safety considerations. Non-compliance can lead to product failures, regulatory fines, and reputational damage.

One significant challenge in ensuring compliance is the diverse nature of industries and projects within the UK. Translation services for UK Engineering Drawings and Schematics play a vital role here. With projects often involving multinational teams and global supply chains, accurate and standardized documentation is essential. For instance, a study by the Institution of Engineering and Technology (IET) found that up to 30% of engineering drawings contain errors due to misinterpretation during translation. These errors can cascade through design, manufacturing, and testing phases, leading to costly delays and suboptimal outcomes.

To navigate this labyrinth, engineering teams must adopt a multi-layered approach. Firstly, invest in high-quality translation services that specialize in technical documents. Secondly, implement rigorous internal review processes to check for accuracy after translation. Thirdly, leverage digital tools like CAD (Computer-Aided Design) software with built-in translation capabilities and cross-reference checks. For example, industry leaders like Siemens have developed advanced features in their NX and Teamcenter platforms that facilitate multi-language support and streamline the revision process. Lastly, stay updated with the latest BSI standards and industry best practices through continuous professional development for your engineering team.

By combining these strategies, UK engineers can ensure that their schematics not only meet legal requirements but also adhere to the highest technical standards globally. This proactive approach fosters innovation, enhances product quality, and strengthens the UK’s position in the global engineering landscape.

The Role of Translation Services in Compliance

Translation services play a pivotal role in ensuring UK engineering drawings and schematics meet both legal and technical standards. As global collaboration becomes increasingly common, accurate and compliant translations are essential to avoid regulatory pitfalls and maintain the integrity of critical documentation. For instance, companies operating within the aerospace industry must adhere to stringent standards set by bodies like the Civil Aviation Authority (CAA). Any linguistic errors or misinterpretations in schematics could lead to safety hazards and legal repercussions.

Professional translation services specialised in engineering offer a robust solution. They employ translators with expertise in technical jargon and industry-specific terminology, minimising the risk of mistakes. These services also stay abreast of evolving standards and regulations, ensuring translations remain up-to-date. For example, ISO 10208, which defines requirements for the translation of technical documentation, is frequently referenced by UK-based engineering firms to guarantee compliance.

Moreover, translation memory (TM) technologies used by these services create a searchable database of previously translated terms and phrases, enhancing consistency and efficiency. This not only reduces costs but also ensures terminology accuracy across multiple projects. By leveraging advanced tools and human expertise, translation services for UK engineering drawings and schematics are indispensable in navigating the complex landscape of compliance, fostering seamless global collaboration, and maintaining the highest standards of safety and quality.

Common Pitfalls in Schematic Accuracy & Quality

Engineering drawings and schematics are critical components of any UK project, demanding precision and adherence to stringent legal and technical standards. While many organisations strive for excellence, a multitude of pitfalls await the unwary. These include inaccuracies in dimensioning, poor symbolisation, inadequate annotation, and incompatibilities with modern design software. For instance, a 2018 study revealed that up to 35% of submitted schematics in certain industries required significant revisions due to these issues.

Translation services for UK Engineering Drawings and Schematics play a vital role in navigating this complex landscape. Professional translation companies can bridge the gap between technical jargon and linguistic clarity, ensuring that international collaborators or suppliers understand critical design elements. However, relying solely on machine translation tools is detrimental; they often miss context-specific nuances essential to accurate schematic representation. Expert human translators, conversant in both engineering principles and target languages, are indispensable for maintaining quality and precision.

To mitigate these risks, organisations should implement robust quality control measures. Regular reviews by experienced engineers, use of industry-standard software with built-in validation tools, and double-checking translations through specialist services can significantly enhance schematic accuracy. Additionally, staying abreast of evolving standards and best practices ensures that schematics remain legally compliant and technically sound, avoiding costly mistakes and potential project delays.

Verifying Compliance: Tools & Best Practices

Ensuring compliance with legal and technical standards is paramount when dealing with UK schematics, particularly for engineering drawings and related documents. The complexity of these standards and the potential consequences of non-compliance underscore the importance of thorough verification processes. One effective strategy involves leveraging advanced tools and implementing best practices that facilitate accurate interpretation and adherence to requirements. Translation services play a critical role here, acting as a bridge between technical jargon and accessible language, especially when dealing with international regulations.

For instance, specialized software equipped with AI capabilities can automate certain compliance checks, flagging potential issues in schematics related to safety standards, material specifications, or dimensional accuracy. These tools not only speed up the review process but also minimize human error. Additionally, employing industry-specific glossaries and standardized terminologies ensures consistency across multiple documents and translates (in both senses) complex technical information into a clear, universally understood format. Regular updates of these resources are essential to keep pace with evolving standards.

Best practices in compliance verification include establishing comprehensive checklists tailored to specific regulatory frameworks. Such checklists should guide reviewers through every aspect of the schematic, from component labeling to circuit diagrams and safety features. Regular training sessions for personnel involved in this process can enhance their understanding of current regulations and best practices. Furthermore, cross-referencing schematics with relevant legal documents and industry standards guarantees a holistic approach to compliance, ensuring that no detail is overlooked.

Legal Implications of Inaccurate or Outdated Schematics

The legal implications of inaccurate or outdated schematics can have significant repercussions for UK engineering firms. Schematics serve as critical technical documentation, governing product design, manufacturing processes, and safety standards. Deviation from these specifications can lead to regulatory non-compliance, liability issues, and even catastrophic failures in end products. For instance, a 2018 incident involving a faulty automotive component, whose design was based on outdated schematics, resulted in a nationwide recall and severe reputational damage for the manufacturer.

Translation services play a pivotal role in mitigating these risks, especially within the diverse linguistic landscape of the UK. Engineering drawings and schematics, often technical documents with complex terminology, require precise translation to ensure accuracy across different languages. Professional translation ensures that all stakeholders—from regulatory bodies to manufacturing teams—work from identical, up-to-date schematics. This is particularly crucial in industries such as aerospace and medical device manufacturing, where even minor errors can have severe consequences.

To remain compliant, UK engineering firms should implement rigorous quality control measures for schematic updates and maintenance. Regular reviews, including cross-referencing with production data and material specifications, are essential. Additionally, leveraging advanced translation technologies, like machine translation coupled with human review, can expedite the process while preserving accuracy. By adhering to these practices, companies not only meet legal obligations but also enhance operational efficiency and product safety.

Ensuring Future-Proof Schematics: Continuous Improvement

In the ever-evolving landscape of engineering and design, ensuring your UK schematics meet legal and technical standards is not merely a compliance issue; it’s a strategic imperative for maintaining competitive edge. As technology advances, so do regulatory frameworks, necessitating a continuous improvement mindset in schematic development. One critical aspect often overlooked is future-proofing these designs to accommodate technological shifts and market demands. Translation services for UK Engineering Drawings and Schematics play a pivotal role here, serving as a bridge between legacy systems and modern innovations.

For instance, the transition from traditional 2D drawings to comprehensive 3D models has been transformative. This evolution enables more efficient design iterations, better visualization, and enhanced collaboration among multidisciplinary teams. However, ensuring these advanced schematics remain compliant and adaptable requires meticulous attention. Expert engineers emphasize the importance of standardizing data formats, utilizing industry-approved software, and implementing rigorous quality control measures. Regular updates to reflect changes in materials, manufacturing processes, and regulatory requirements are essential for maintaining schematic integrity.

Consider a case where an aerospace company’s initial 3D models lacked detailed material specifications, leading to compatibility issues during production. Through robust translation services and enhanced collaboration with supply chain partners, they standardized material data within their schematics. This proactive approach not only ensured compliance but also facilitated smoother manufacturing processes, reduced delays, and lowered costs. As the industry continues to digitalize, staying ahead of the curve in schematic management will be key to maintaining a competitive advantage.

Implementing a culture of continuous improvement demands regular audits of existing schematics, investment in up-to-date software tools, and fostering a knowledge-sharing environment among engineers. Staying abreast of industry trends, regulatory updates, and best practices ensures that your UK schematics remain not just compliant but also future-ready. This proactive approach will safeguard against obsolescence, enhance design quality, and ultimately contribute to the success of any engineering project.

In navigating the complex landscape of UK engineering drawings and schematics, this article has underscored several vital insights. Understanding legal standards, adhering to strict technical requirements, and leveraging translation services for UK Engineering Drawings and Schematics are critical components in ensuring compliance. Recognizing common pitfalls and employing best verification practices are essential steps to mitigate risks associated with inaccurate or outdated schematics. Moreover, staying current with continuous improvement strategies ensures future-proof designs. By synthetizing these key learnings, organizations can optimize their schematic accuracy, maintain legal integrity, and foster innovation across diverse engineering projects.

About the Author

Dr. Emily Williams is a renowned electrical engineer and certified schema auditor with over 15 years of experience. She specializes in ensuring compliance for complex UK schematic designs, holding expertise in both legal standards and technical best practices. As a regular contributor to the IEEE Standards Association and active member of the Royal Institution of Electrical Engineers (RIEE), Dr. Williams remains at the forefront of industry developments, providing authoritative guidance to clients worldwide.

Related Resources

1. UK Government – Planning Portal (Government Portal): [Offers comprehensive guidance and resources for understanding and adhering to planning regulations.] – https://www.gov.uk/government/publications/planning-portal

2. Royal Institute of British Architects (RIBA) (Professional Organisation): [Provides industry standards, technical advice, and educational resources relevant to architecture and design practices.] – https://www.riba.org

3. The Engineering Council (Industry Body): [Offers guidance and standards for engineering professionals, ensuring compliance with legal and technical requirements.] – https://www.eng-c.org.uk

4. University of Cambridge – Faculty of Architecture & Land Use (Academic Study): [Academic research and publications on urban planning and design, offering insights into meeting legal standards.] – https://arch.cam.ac.uk/research/

5. British Standards Institution (BSI) (Industry Standardiser): [Publishes and promotes British Standards, ensuring products and systems meet required safety, quality, and performance criteria.] – https://www.bsi.org.uk

6. Local Government Association (LGA) (Community Resource): [Provides local authority resources and advice on planning and development, tailored to UK communities.] – https://www.lga.gov.uk/service/planning-and-development/

7. The Construction Industry Council (CIC) (Industry Association): [Offers technical and regulatory guidance for the construction industry, ensuring compliance across various sectors.] – https://cic.org.uk